|

|

Post by penguin45 on Mar 3, 2017 16:22:45 GMT

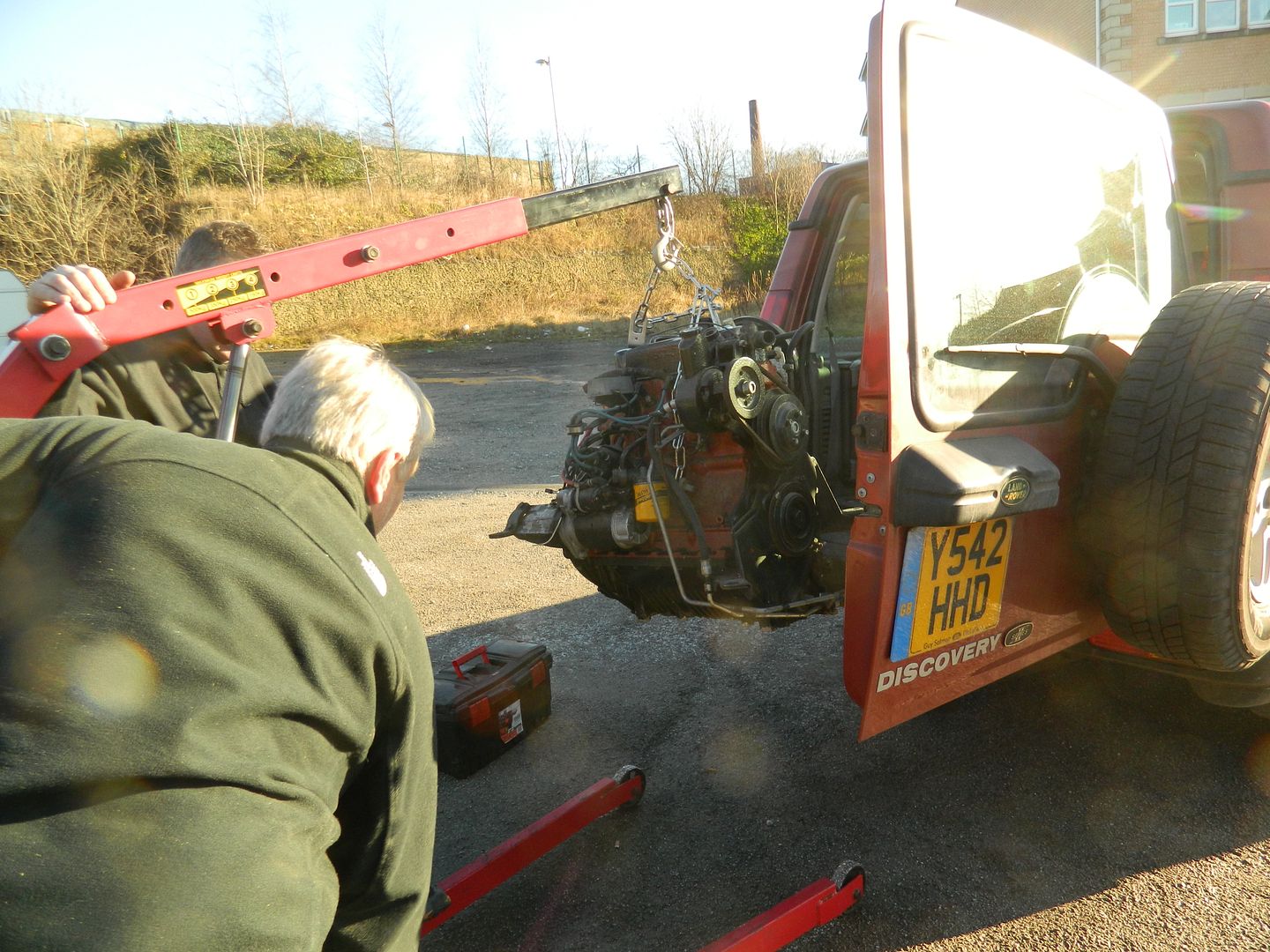

This started off in all innocence last summer. The Gold Seal engine which I had fitted to Eugenie a couple of years back was using a bit of oil and gradually getting worse. A refurbished low mileage 1800 Princess appeared on eBay repeatedly. I finally cracked and bought it silly cheap. A road trip down to Cardiff with my mate mark saw it lugged back up to Yeadon in the back of the WifeBus.   Not bad for £50 and half a tank of fuel. And then, it just sat there, as did Eugenie as she was now using more oil than fuel. I was snowed under with the series of restorations detailed in this forum and was eventually contacted by the shadowy organisation known as "WOLF".  Then:      And they were gone...... P45. |

|

|

|

Post by penguin45 on Mar 5, 2017 19:46:03 GMT

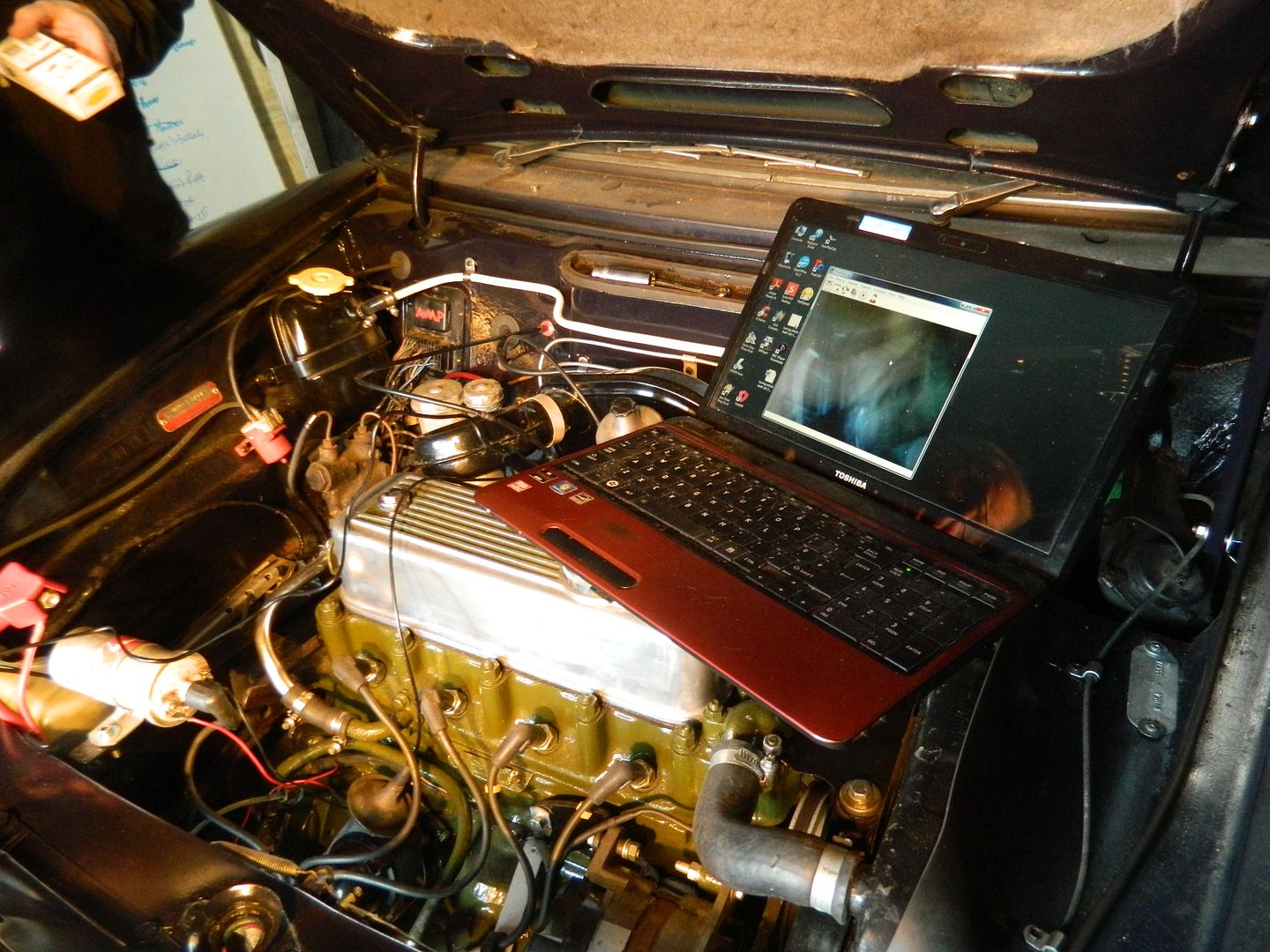

A bit of time went by and the odd demand for more HobNobs and some parts were received; and the occasional photograph.  Here the engine has been stripped of its Princess bits, painted and the 1800 gubbins installed.  Then there was this one - engine bay has had a lick of paint and the motor dropped back in. Finally. Snoopy rang up to say it was ready. Saturday came and he collected me in the XK8 (nice........). Off over to the hills above Nelson. I thought we'd have a cuppa, settle up and then head down to Preston for a spot of Princess fettling (See It's not a Princess on this board). Engine fired up nicely and settled to a smooth, steady, quiet idle. Jumped in to pull it out of the barn and couldn't engage a gear. Turn off engine, can engage gear. The slave cylinder appeared to be damp. Investigations under the dash showed a trace of hydraulic fluid from the master cylinder. Off they came.   Cleaned and re-rubbered.  This is an extremely rare picture, as it features me working on one of my cars. I'm re-fitting the clevis pin under the dash. System was bled up, unable to select gear. Raised the front wheels and tried banging it free with the brakes. Nothing doing. Ultimatley came the sight I thought I would never see on a 'Crab.  Computer diagnostics..... Actually, it's a miniature boroscope and we were looking inside the bell housing. So clutch friction plate is stuck fast and all sensible ways of freeing it have failed. Next Saturday we'll take the engine out.  So, funny sort of day. Hopes raised and dashed in short order. It never occured to me that the car hadn't moved. I mean, if I stuck an engine in your car, I'd be off for a spin round the block at least, just to enjoy my handiwork. Ho hum, P45. |

|

|

|

Post by Matt of the Vivas on Mar 5, 2017 22:08:59 GMT

Run the engine till its properly hot - an hour or more. Then wedge the clutch pedal down overnight.

A packet of chocolate hobnobs says its free in the morning. Works every time.

|

|

|

|

Post by penguin45 on Mar 6, 2017 10:51:52 GMT

Run the engine till its properly hot - an hour or more. Then wedge the clutch pedal down overnight. A packet of chocolate hobnobs says its free in the morning. Works every time. Thanks, Matt. I've passed that one on. Chris. |

|

|

|

Post by harvey on Mar 6, 2017 16:37:43 GMT

Run the engine till its properly hot - an hour or more. Then wedge the clutch pedal down overnight. Plus, leave it in gear with the front wheels half way down a set of ramps and providing gravity doesn't overcome the compression then it will load the stuck plate up even more and when it frees it will just roll down the ramps. Just did one last week and it freed off straight away, so much so that initially it was thought it was just the engine turning over. To tempt fate, in 45 years I've never had to remove a box to free one off. There, that's put the kybosh on it now...... |

|

|

|

Post by penguin45 on Mar 6, 2017 16:54:52 GMT

Ingenious. I've passed that one on as well. Thanks.

P45.

|

|

|

|

Post by penguin45 on Mar 11, 2017 0:32:07 GMT

Matt wins a packet of biccies.  I should be picking her up in the morning. p45. |

|

|

|

Post by Matt of the Vivas on Mar 12, 2017 19:03:23 GMT

Make sure they are milk chocolate, im offended by dark chocolate.

|

|

|

|

Post by penguin45 on Mar 14, 2017 18:50:06 GMT

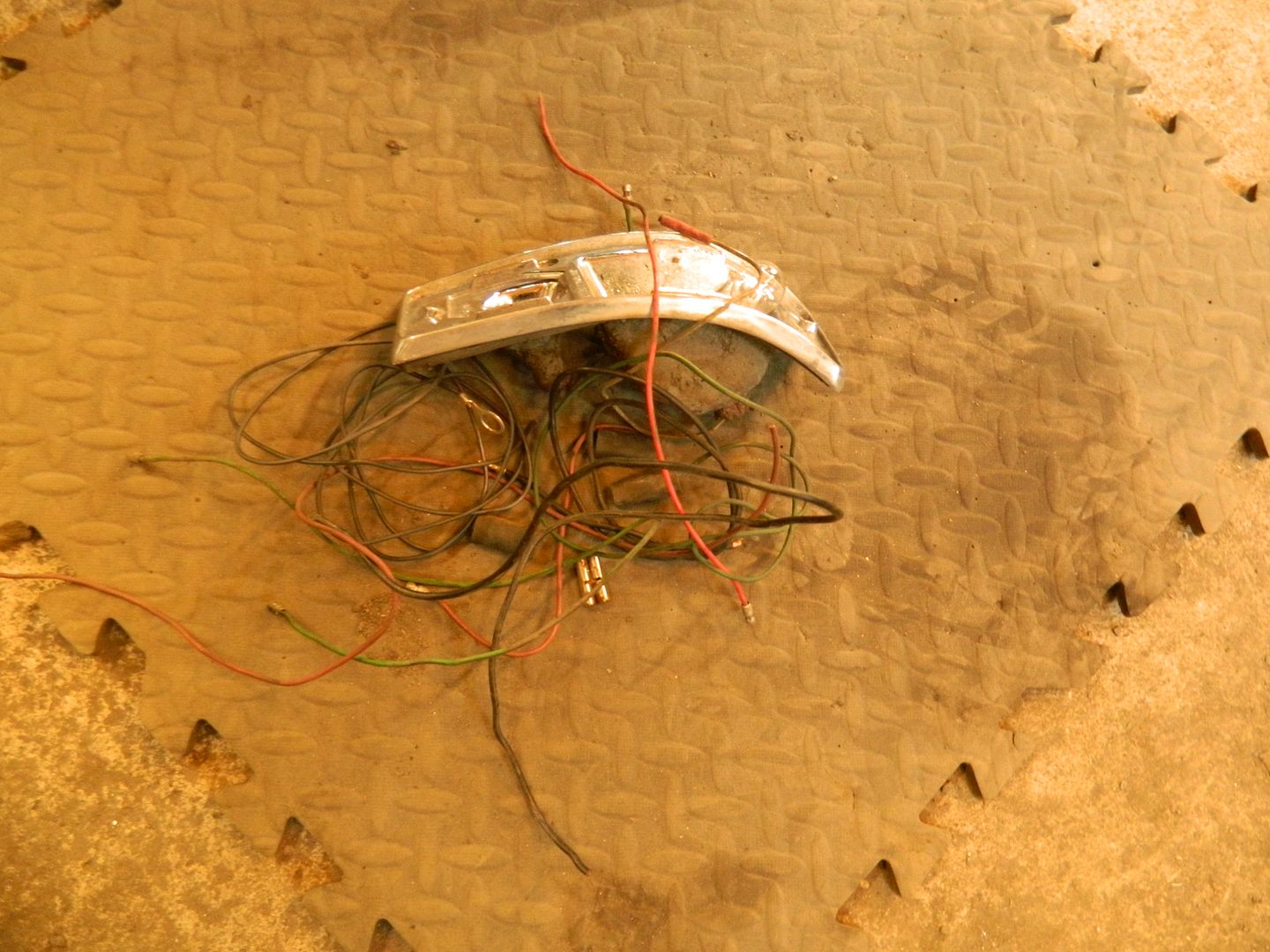

Should have updated this! Gordon managed to break the clutch free during last week, so picked her up on Saturday and drove from the heights above Nelson down to Preston to join Nishka and Ron for the barn day. Broke down three times..... Rotor arm with a rivet, then the dizzy decided to move and then she boiled when I hit some slow traffic. Apafrt from that, it just drove like an absolute nail, spitting, popping, banging and juddering like  . I'm still not quite sure how I managed to get back to Yeadon. Locked her up in my spotlessly tidy garage and went to the pub. Sunday morning I went to help Stuart, so Sunday pm saw me reaching for the chain saw sorting things out. The basic problem was she was running manically rich and it proved impossible to weaken it properly. Took carb off - an SU HS6 with a Waxstat set up on the main jet. Oh dear..... It didn't work 40 odd years ago; why did we ever think it would still be working now? Off with the Princess linkages and brackets, on with the recon 'Crab carb. Off with Gordon's dizzy ('cos it's the one from his "S") and on with a refurbished one. Then I added the 1970's electronic ignition unit which came with the engine. The engine didn't even complete a full revolution - it fired instantly and settled down to a slightly high idle.  Set up the timing and mixture and sounds as sweet as a nut. Monday and today pm saw me getting the electrics fully functional across the front of the car. Don't know what the fuss was all about.  That's what got cut out and replaced.  Side lights.....  ......Blackpool illumination. P45. |

|

|

|

Post by penguin45 on Mar 16, 2017 0:33:53 GMT

Took her out for a test drive this afternoon. Much better. Ignition has been advanced slightly as it felt like she was holding back under acceleration. Might need to be enriched a smidge, but I'll try the ignition first. Interesting noises from the front left suspension means that she's back up on the stands for investigation again.

P45.

|

|

|

|

Post by penguin45 on Mar 16, 2017 20:14:38 GMT

"Interesting noises from the front left suspension" proved to be a mild understatement. I nipped up a slightly loose ball joint, then dropped the tie-bar housing.  Not nice. Not nice at all. The only thing stopping the bar pulling clean through was the large cup washer on the end of the front rubber bush, which was just large enough not to go through the hole. Potentially lethal.  And compared with a rather scruffy example with a sound centre panel.  That's been cleaned up and a welded repair made to the rear cover section. Now painted, so it can be reassembled tomorrow. P45. |

|

|

|

Post by penguin45 on Mar 17, 2017 21:14:10 GMT

Paint dried nicely overnight, so bolted it all back together this afternoon. Tweaked the timing and Bingo! - smashing drive. Will take her over to Preston tomorrow and see what a proper run is like. I have put a tool box in the boot.......

P45.

|

|

|

|

Post by penguin45 on Mar 23, 2017 19:34:32 GMT

Very pleasant was the answer. Anyway, back in the garage for other bits and bobs, starting with new ducting in the wing.   Not quite as rigid as I wanted, but not completely floppy. Ooh err Mrs... Tied off at four points, so it won't go anywhere. This also revealed that the outer end of the valance is going to need some love sooner rather than later. Then there were the two scabs on the end of the sill. Just had to poke them.   A short time later:  So that's the door got to come off to release the wing and get out old Sparky again. Chris. |

|

|

|

Post by penguin45 on Mar 24, 2017 21:23:00 GMT

And the second going over left this.  Cut to a sensible shape with the slitting disc. Just goes to show how much you have to cut away to get to sound metal - if you don't, you're just wasting your time.  And a short while later. Sorry about the rubbish phone pics. P45. |

|

|

|

Post by penguin45 on Mar 25, 2017 18:20:37 GMT

Finished that off today.  Etch, then seam sealer, primer, some random blue top coat followed by stone chip underneath and underseal up the A post.  Cleaned up the wing bottom and welded a new tag for welding under the sill.  And a couple of coats of colour to finish. Doesn't look bad at all despite the rubbish pictures. Whilst waiting for the various layers of paint to dry, I sorted out the window mechanism in the door. It has to come off to release the rear edge of the wing. The glass had separated from the lifting channel. Removing the lifting channel showed plenty of rust and distortion. Welded in a new section, straightened everything out and (at the third attempt) got the gap for the glass and its rubber right, so raising the glass to the fully closed position and a little bit extra on the winder saw everything pushed back together. Yay! I didn't have to remove the actual mechanism and indulge in octopus wrestling. Door back on tomorrow, then I can fit the new ducting in the other side. And see what other horrors are revealed.... P45. |

|